IN-DIE SPOT WELDING

R&M Highspeed Stampings provides streamlined precision metal stamping processes

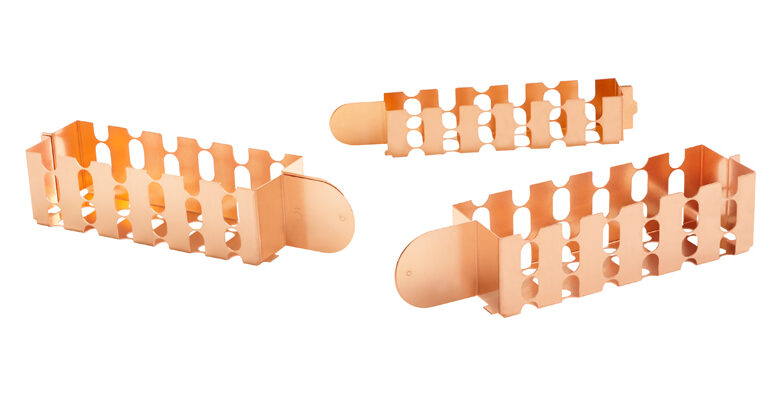

In-die spot welding is a welding process during which spot welding is conducted in the tool with every cycle of the stamping press. This is a highly automated welding process that requires precise machinery to quickly and efficiently combine spot welding and stamping into a single, seamless process.

In-die spot welding offers the benefit of taking what are typically two completely separate processes—stamping and spot welding—and combining them into a single operation. In addition to drastically reducing the time required to produce a finished stamped component, it also eliminates the potential for human error during the production process.

This process requires incredibly complex and precise machinery, and regular upgrades to accommodate the most innovative technologies is often necessary. R&M High Speed Stampings positions itself as a cutting edge precision metal stamping manufacturer, and we pride ourselves on providing industry leading services, technologies, and finished goods from concept through production.